I’ve never asked a pro but somewhere in my decades of DIY I got the idea that the right way to connect outlets in one box is to branch them all off the incoming wire so they’re in parallel. In the photo each little metal strip between the screw terminals on each outlet is carrying all the current from all 6 sockets, which I don’t think is proper.

I don’t think it’s the current in the tabs that’s an issue, each socket should be rated for the full circuit’s rating, but the ground shouldn’t be in series, always parallel.

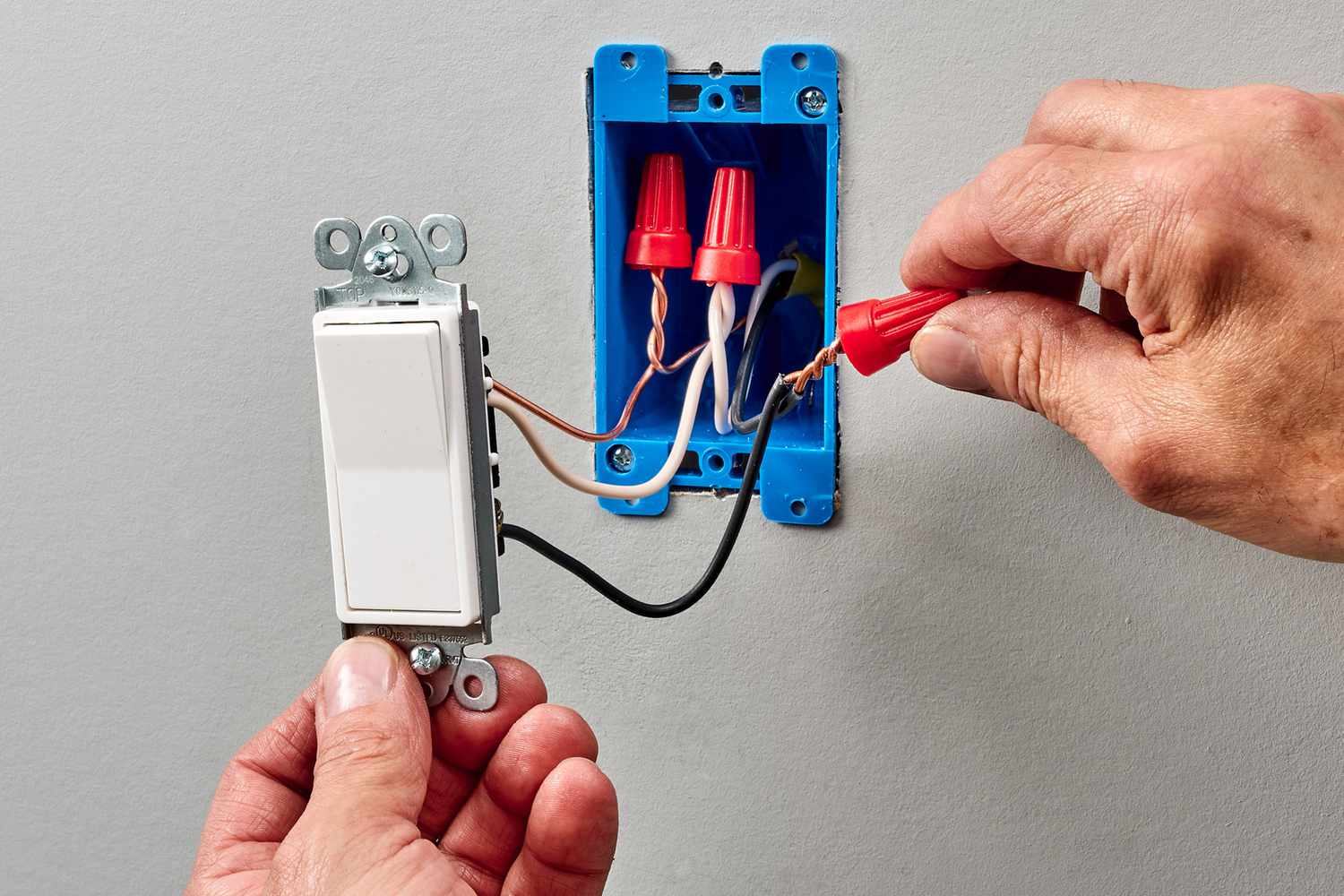

One suggestion. Some of the terminals are wrapped counter clockwise to the screw.

You want them to be looped in such a way that when the screw is tightened the loop is pulled into the screw instead of being pushed away from it.

You can see the way it’s wired here. Each one relative to the screw.

I remember when my gramps showed me that when I was about 12 and was helping him wire in his house.

wish he was still around, old timers had alot of wisdom and tricks I don’t see anymore. (they also did some really FUBAR things too 😆)

Thanks :)

I am not an electrician but I do try to follow code as closely as possible when I do this and all guidance I’ve ever read says to pigtail each receptacle or switch individually. It takes up a lot of room in the box, but if you use waygos or ideal push in connectors, it opens up a lot of room.

I do love waygos, so convenient

buddy system

I’m in love with using wago lever nuts for this stuff now. Makes later maintenance so much easier, and totally avoids wire nuts. Manages to be less wire stuffing in the box too.

now imagine having to be the one in 20 years that has to replace the first or second plug.

doing that myself recently. 😮💨

Don’t forget to wrap electrical tape around the edges of the units to cover up the screws. It prevents any accidental short if you happen to touch anything in the wrong way. Makes it especially safe when installing and uninstalling in the future.

I used to just put things in after wiring without a thought for the longest time. Then an old electrician taught me to do this as another added bit of safety.

… and beautiful job … love when things like this come together. Hope everything else works out in your project.

Oddly enough no electrical tape on twist connectors.

They should be tight enough to hold the wires together and adding electrical tape just makes it harder to see if they’re loose or coming loose.

Personally I love WAGOs for that and they’re cheap enough now.

I’ve never used wagos but I want to

Wago connectors are life changing. They’re not as compact for large bundles, but feel ten times more safe in use.

I didn’t know you could daisy switches like that

They’re outlets

You can, but the switches downstream won’t work if the switches upstream are off. These are power outlets, so it’s fine.

Electrically sure, and I believe legally. However it’s not the best choice because you’re introducing more points of possible failure.

I wasn’t going to say anything because this is art.

No pun intended, but why not stick the wires into the appropriate holes? Why did you choose to wrap them around the screws?

I don’t like the holes. I don’t trust em. With the screws I can definitely see what’s going on.

I’ve got a bit of rewiring to do in my home soon and have been doing some research. Apparently this is called backstabbing and is generally considered lower quality work. The connection simply isn’t as secure as the screw tightened half loops on the side - but if you spend all day everyday wiring receptacles it’s much faster to backstab. Backstabbing is to code, but if you’re wiring a few receptacles, best to take the few extra minutes to do it the more secure way.

Backstabbing is to code but really shouldn’t be. They can cause fires as the connection gets looser over time as the device is used and isn’t nearly as secure.

The contact area of the terminals on the wires is much higher if you use the screws rather than the dinky little spring prongs in the stabby-holes. A small contact area means more heat is produced at the junction, which leads to premature failure, which leads to annoyance, which leads to the dark side.

The only outlet I witnessed fail due to heat was backstabbed.

I hate backstabbing because trying to get it off when you need to work on the receptacle is usually a big pain in the ass. I actually broke part of an outlet once. I was replacing it anyway, but damn.

Probably 99% of electricians will tell you to never use the back stab holes.

They don’t hold well, at all, are easy to pull out when pulling an outlet/switch out, and can break the casing when trying to push the fixture in.

I don’t understand how they ever got approved, they’re flat out dangerous.

Never use the backstabbing holes on electrical receptacles.

They come loose over time, faster if they’re not fastened properly or if the house is prone to settling.

I’m convinced this is a myth or only happens when people don’t actually push it in far enough. For me, it’s always been a pain in the ass to remove them. Which is why I hate it.

Never seen a loose one either, but that doesn’t mean they don’t exist. I bet some manufacturer had a bad batch.

Definitely not a myth. They are notoriously failure prone. Repeated expansion and contraction and just age can cause the contacts to loosen, which increases resistance, which increases heat generated at the point of connection, which increases the amount of expansion and contraction, etc.

A lot of people don’t even realize they have a problem until they plug in something high wattage like a space heater or hair dryer and the outlet gets nice and hot.

I’ve seen them be loose every time I’ve encountered them. And some of them were my own doing before I discovered they work loose, and just suck in general (and are disliked by electricians).

I’ve pulled out receptacles where the wire popped right out and stayed in the box. It could have been installation error by the previous homeowner or poor quality receptacles. All I know is that’s what my electrician friend who was helping me told me.

Is THAT what the holes are for?!?

I honestly never knew.

You press the wire directly into the round hole. To remove, you need to stick a small screwdriver into the rectangular hole next to it.

No one uses holes. They have a high fail rate, the Unless they are the high-end outlets where the screw also clamps the wire in the hole. And still, no one uses holes.

I use the holes, they’re just easier. Never had one fail.

Most old work I take apart also uses the holes.

Lol yeah I did in the past, too. Then I learned why they suck and why we should not use them. And to be honest with you, using the screws isn’t hard. You’re just being lazy.

I do. They work fine.*

- Note: I don’t turn my lights on and off with a sledgehammer or anything, not sure what applications people are needing these for out there. 🤷♂️

It has nothing to do with how hard you smash the switch. It’s the spring retainer mechanism. Over time, the spring weakens and won’t retain the wire in place as well, making it prone to a poor electrical connection. Also, the location of the light switch can play a big role. A light switch by the front door of the house on an outside wall is significantly more prone to vibrations from the door opening and closing and temperature fluctuations. This, in turn, accelerates the spring loosing it’s strength.

Especially with the hearing of current passing through.

I’d like to ask the developer of these things what happens to a spring that is repeatedly heated and cooled…

Can’t tell which those are but

-

“back stab” where it is held by friction, common to consumer receptacles, have a poor reputation for failing. Don’t use them

-

“back clamp” (don’t remember what they’re called), common to “pro” receptacles is clamped down by tightening the screw. Much more reliable

-

I’m not a professional electrician by any stretch of the imagination, but I have done plenty of home remodeling and I’ve literally never seen the backstabbing holes used. Though most of the houses I’ve worked on were built before ~2006

I’ve never considered doing any pre-wiring before shoving stuff in the box.

I’m having a lot of trouble figuring out what’s going on here, but I assume you’ve done your homework OP.

From what it looks like, the switch on the right will have the hot and neutral connections from the panel, and the switch on the left will get connected to the appliance, and the appliance will only turn on if all 3 switches are turned on.

Presumably these are American style outlets, which don’t have switches - they’re always on.

It’s just 3 outlets in parallel.

Ah, that’ll do it.

They’re outlets

That explains it.

Is this up to code in the US? I know Europe is way different in a lot of ways, but this would not fly in Europe.

What’s the problem?

Pigtailing is so ubiquitous where I am that this just looks weird.

I don’t actually know if it’s strictly code in my area, or just common practice.

Pigtails is the code, you are correct.

Exposed copper is a big no-no in the regulations where I live, because it’s a corrosion risk and a shock risk when exposed. Everything needs to be either covered in plastic or be coated in something corrosion resistant (for grounding wires for example, even tho those are usually covered in plastic as well depending on the situation).

Loose wires under screws can be applied in very specific situations, but they usually need to be clamped down. And the screw needs to be fully recessed so it’s not something that can get into contact with anything else. Daisy chaining is also usually not done, but depending on the situation it can be allowed even though it isn’t recommended.

Keep in mind European rules and regulations are way different and even different per country. And what the rules say and the shit people actually pull isn’t the same either. The most interesting difference to me is the amount of metal used in American systems, where Europeans systems are usually as much plastic as possible. Even if metal is required for some reason, it’s usually fully covered with plastic. At the same time in Europe having ground fault interrupters (or comparable, it isn’t exactly the same) are not only standard but usually required.

The exposed copper is the ground wire. How’s it done where you are?

Grounding wire is just like regular wire over here. The colors we use are: Blue for the neutral, brown for the hot and green/yellow for earth/ground.

There are more colors for other situations, but these are the most used. Black is also used a lot and usually means a switched hot, so brown to a switch and black to for example a light fixture. These are often done in a thinner gauge because the switch can’t switch a big load anyways and usually lights don’t use that much power.

Normal gauges are 2.5mm2 (14 AWG) for regular 16A circuits and 1.5mm2 (16 AWG) for switched circuits. Keep in mind this is at 250V, so 16A gives you a hecking lot of power (4000 watt continuous load). The circuits are designed such you can even go a bit above this for a short time. The wires are designed to handle 25A without any issue, but are limited by the protection equipment (“fuse”). All wires need to be single stranded, multi stranded can only be used in specific situations, never in permanent installations (except for shielding wires which are usually by definition stranded and will normally never carry any current).

Well the exposed wire is a ground.

Ok yes, it would be better to screw in those screws.

I hate GFIs. They take up so much room in the box. Here (IL USA) code says to use em in bathrooms and kitchens. Like within 10’ of water or something.

In Europe all the GFIs and such are in the central switch box, not at the outlet. Because everything needs to be protected it’s useful to have it all in a central place. The way it is incorporated can be complex, but there can be just one for the entire house. But usually there are much more, depending on how the place is wired up and how recent it is.

You can wire a GFCI outlet to have it protect everything after it. Pretty common in kitchen and bathroom situations where GFCI are required.

In the US you’ll see circuits where the GFI is elsewhere (so one circuit is protected).

We’re starting to see the GFI in the panel.

Can be here too, but usually isn’t. It’s just an annoying shortcut.

Originally there weren’t such breakers and you only needed a limited number of gfci’s so it was cheaper to use protected outlets. Now it’s just annoying, although there’s the convenience argument of having the reset right there at point of use

We do it both ways. New construction vs old construction basically. I never put a GFI in a breaker box tho. I assume it’s just a fatter breaker.

Yeah it’s usually a 2 unit wide thing, that connects to a max of 4 breakers that protect the (usually) 16A circuits. However recently it has become the norm to just integrate the breaker and the ground fault protection and those can be as thin as 1 unit. So the size of a normal breaker.