I always wondered this since I noticed that a lot of cars always have at least some damage to their pinch weld jack points, usually from hydraulic jacks, lack of adapters, or dropping the car onto jack stands hard. I get it not everyone has the right equipment or experience but it also seems like a poor and cheap design from the manufacturers. Why hasn’t there been a method or aftermarket product that kinda bulks up the pinch welds. Hell I don’t think I ever seen someone even weld or bolt on some steel to kind of guard the pinch welds from bending. Is there a reason for that, like structurally? Why are those hockey puck looking adapters the norm, just because its easier?

Tldr: Many vehicles suffer damage to their pinch weld jacking points from improper use of jacks, prompting the question of why there isn’t a robust aftermarket solution or protective design from manufacturers to prevent this issue, besides those hockey puck looking adapters?

They make jack adapters for this exact reason. I’ve seen them for lifts as well.

I drive a hot hatch and purchased aftermarket jacking rails for it. The rails are two long pieces of steel that I bolted underneath the car to distribute weight. I can jack the car up from anywhere along those rails.

Alternatively there are also jack pads you can buy for pinch welds. It’s just a block that you set on top of your jack. As you raise it to the point of the pinch welds, the jack pads surrounds it and helps distribute weight and support the car better.

I get it not everyone has the … experience

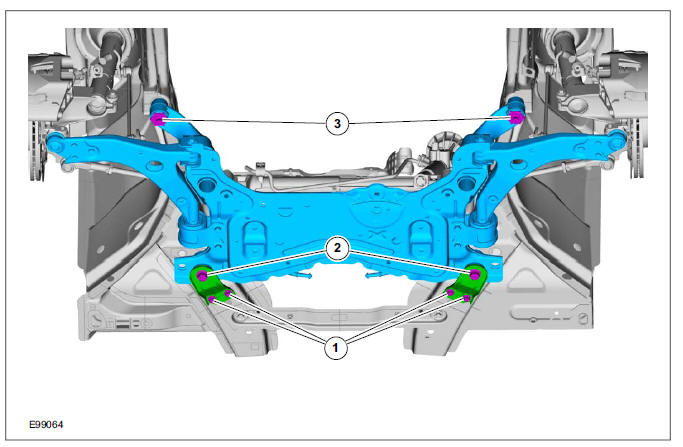

This is really what it boils down to. I never had this issue as a mechanic, but I didn’t generally use pinch welds as a jack point. Most vehicles have numerous options for using a floor jack. You could use a control arm, or cross member, or sometimes a drivetrain component. Additionally, sometimes the pinch weld has a designated spot for jacking that seems to be reinforced.

Maybe what you are saying only applies to newer vehicles and I am out of date. Totally possible! I did not experience this 10+ years ago, tho. Only on exceptionally rusty cars that the driver would be challenged to install thr spare on the side of the road.

deleted by creator

I can’t remember what they are called, but I’ve seen what looks like round pieces of dense rubber with a slit for the pinch weld to sit in.

Picks.

Because it’s usually pointless to anyone that knows how to work on cars. I use the frame. Because it’s where I’m going to put a jack and it’s faster. The only one I use is on one side of my Camaro to lift it high enough to use the frame on the other side because it’s lowered. They may get damaged but it’s only use is the side of the road to change a tire.

Unibody cars, as in, the ones with the pinch welds under discussion, don’t have a frame

The sheet metal is the frame.

Which, in my opinion, is why nobody gives a shit-any car built like that was built to be disposable fucking garbage.

Unibodies do have a frame it’s just not a completely separate assembly like a ladder frame.

As others have said there are lots of places to jack a car. Nobody uses the flange on the rocker panels unless they’re trying to change a tire roadside with the emergency jack.

Exactly, jack points are an afterthought, it might have to be lifted for changing a flat, but otherwise it’ll be on a lift platform at a shop, you’re not hoisting it on Jacks at home to do work on it.

I mean, yeah I am. I don’t trust a shop to do it

There’s almost always a subframe, and where it bolts to the car is my go-to jack point. Bolt #2 would get it.

This must be on modern monstrosities, I’ve literally never encountered this.

The newest vehicle I’ve ever had was a 95, and I am entirely unimpressed with anything made before 93

deleted by creator

I have FM frame rails on my car. While obviously this is not specifically for the jack points, it does significantly reinforce them. That’s kinda similar.